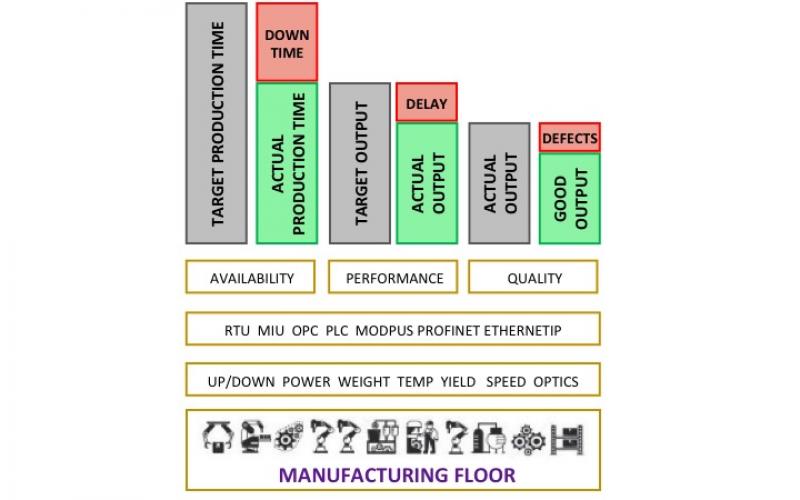

You may not think your company is involved in the Internet of Things, but traditional businesses have been using digital technology in industrial capacities for years. Energy, healthcare, transportation, and public safety use remote sensing and monitoring in a multitude of ways. Production lines on manufacturer factory floors are dotted with sensors that monitor output, temperature, defect rates, energy consumption, and other data of vital interest to plant managers.

This operational technology (OT) has historically been fully segregated from the enterprise information technology (IT) environment. That's largely because OT systems were specifically designed to address factory floor requirements, which are substantially different from the knowledge work requirements fulfilled by IT. Production line management also tends to be somewhat self-contained -- as opposed to knowledge work, which inherently requires interaction across organizations.

Segregation of OT and IT, however, is rapidly becoming a thing of the past. Factory floor telemetry is of growing interest to business leaders who are looking for new ways to increase operating margins and enhance value propositions to demanding customers. Manufacturers also want to take advantage of IP network connectivity to give plant managers remote access to factory floor data.

As a result, OT environments are being integrated onto the enterprise network.

This integration raises a variety of issues for IT. In fact, OT-IT integration can touch every area of IT --including network design, data management, DevOps, and cybersecurity.

To learn more about IoT and its impact on IT, attend the Internet of Things Summit at Interop Las Vegas this spring. Don't miss out! Register now for Interop, May 2-6, and receive $200 off.

(Image: zhaojiankang and gogo_b/iStockphoto with modification)